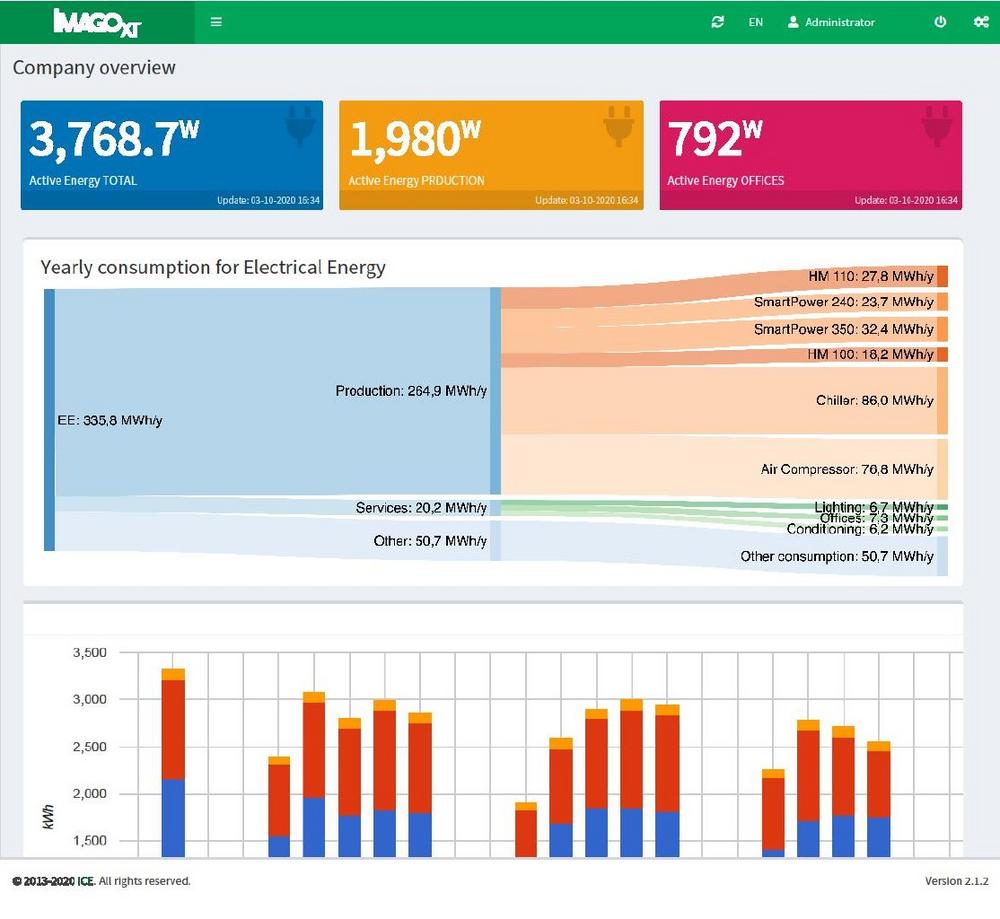

WITTMANN BATTENFELD is introducing a new tool to visualize and monitor the energy consumption and flows within a company. The new software module is called IMAGOxt and is perfectly optimized to interact with the MES solution TEMI+. It deals with energy consumption and much more!

This new IMAGOxt package will allow users to:

- Calculate a detailed energy cost analysis of the company

- Create customized KPIs

- Create personalized reports and alarms,

- Control the company’s energetic performance.

IMAGOxt is able to collect data from a wide network of metering systems installed in the company and interact directly with TEMI+. By processing this information, the software provides analyses, graphs, reports and meaningful KPIs.

Thanks to its intuitive graphic visualizations, IMAGOxt will make it easy for operators to understand their energy consumption trends and immediately detect sources of waste and improvement potentials.

This enables company staff to evaluate new corporate procedures and energy efficiency interventions more accurately, to estimate payback periods and make strategic decisions based on real data.

The WITTMANN Group is a worldwide leader in the production of injection molding machines, robots and auxiliaries for the plastics processing industry, headquartered in Vienna/Austria and consisting of two main divisions: WITTMANN BATTENFELD and WITTMANN. They jointly operate the companies of the group with eight production plants in five countries, and its additional sales and service companies are active with 34 facilities on all important plastics markets around the world.

WITTMANN BATTENFELD pursues the further expansion of its market position as an injection molding machine manufacturer and specialist for state-of-the-art process technologies. As a supplier of comprehensive, modern machine technology in modular design, the company meets both present and future market demands for plastics injection molding equipment.

The WITTMANN product portfolio includes robots and automation systems, material handling systems, dryers, gravimetric and volumetric blenders, granulators, temperature controllers and chillers. With this diversified range of auxiliaries, WITTMANN offers plastics processors solutions to cover all production requirements, ranging from independent production cells to integrated plant-wide systems.

The syndication of the various segments under the umbrella of the WITTMANN Group has led to complete connectivity between the various product lines, for the benefit of plastics processors with an increasing demand for seamless integration of processing machinery with automation and auxiliaries.

Wittmann Battenfeld GmbH

Wiener Neustädter Str. 81

A2542 Kottingbrunn

Telefon: +43 (2252) 404-0

Telefax: +43 (2252) 404-1062

http://www.wittmann-group.com

Telefon: +49 (2354) 72-0

E-Mail: info@wittmann-group.com

![]()