Bearings for railway applications contribute directly to safe operation and travel. High reliability is key, as is the ability to support elevated speeds, improved energy efficiency and reduced maintenance requirements. The demands placed on railway bearings are especially apparent in bullet trains, which transport large numbers of passengers at high speeds over long distances. Applications of this type call for highly efficient and durable bearings, along with meticulous quality control in all production processes.

The ‘S’ suffix of the new-generation N700S bullet train stands for ‘Supreme’, signifying the progression in design, technology and comfort. High-performance bearings from NSK can be found in the gearbox, axle and traction motor assemblies.

Regarding the gearbox, the N700S is the first Shinkansen to replace helical gears with herringbone gears, which offer increased reliability and lower noise output. Gearbox bearings are subject to intense shocks and vibration, so exhibiting a long operational life under these conditions is a priority. NSK has been supplying tapered roller bearings for helical gears in bullet trains for decades. Drawing on this experience, the company has designed a special flanged cylindrical roller bearing for the N700S’s herringbone gears that delivers longer life, lower heat generation and reduced maintenance compared with the previous generation product.

Further benefits of the gearbox bearings used on the N700S include improved seizure resistance, which has been achieved by optimising the design of areas that do not contact the flange face. In addition, a high-strength machined brass cage optimised with NSK’s proprietary R-pocket technology reduces internal stress in the cage structure.

For the axles, the NSK double-row tapered roller bearings used in the previous Shinkansen have been further improved to deliver even higher reliability and reduce maintenance costs. Lower heat generation leading to longer life is a particular attribute.

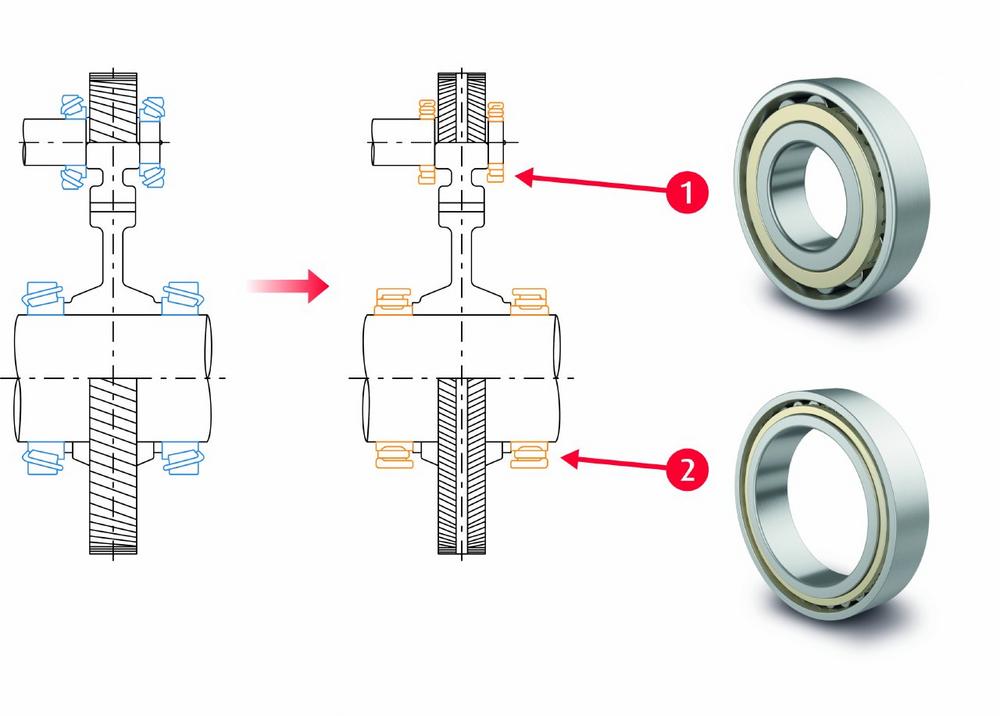

Concerning the N700S’s traction motors, NSK cylindrical roller bearings and deep groove ball bearings feature outer rings that are plasma-sprayed with a ceramic coating. This coating increases reliability by preventing any opportunity for electrolytic corrosion, an unwanted effect that occurs due to the transfer of electrical current through the inside of uninsulated bearings.

NSK has been supporting the advancement of the global railway industry since the company first became involved with the sector in 1932. Bearings from NSK are trusted for their world-class safety, high-speed performance, high reliability and efficiency. Today, the company’s products are used by high-speed rail operators throughout Europe. Close ties with partners in the European OEM and aftermarket sectors help create products that bring about notable advances in this important industry.

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 31,000 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine bearings and steering systems. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2019, the more than 4,400 employees of NSK Europe Ltd. generated sales of over € 920 million.

www.nskeurope.com

NSK Deutschland GmbH

Harkortstrasse 15

40880 Ratingen

Telefon: +49 (2102) 4810

http://www.nskeurope.de

Telefon: +49 (2102) 4811280

E-Mail: pilath-m@nsk.com

Telefon: +34 (600) 780-385

E-Mail: k.matsuo@mepax.com

![]()