Sales of this new profile sensor are scheduled to start from September 1, 2021 mainly for manufacturers of surveying equipment and factory automation equipment.

Product overview

This product is a profile sensor with an embedded computing function designed to detect the incident light spot position.

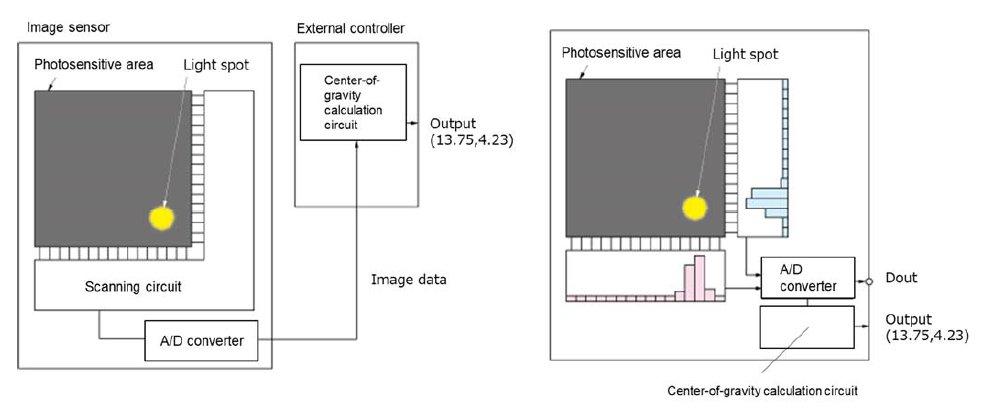

This new profile sensor is a type of CMOS image sensor (complementary metal oxide semiconductor) with pixels arranged in two dimensions. When detecting the position of incident light, ordinary image sensors compute the image data they capture. Profile sensors, on the other hand, process just the projection data and so can rapidly detect the incident light position.

Hamamatsu Photonics manufactures and sells profile sensors for surveying equipment, but until now these profile sensors required an external controller for computing the projection data. This new profile sensor uses a processing chip that contains a computing circuit for calculating the center-of-gravity of the projection data, making it possible to output the incident light position as coordinate data without having to use an external controller. In addition, it has added functions for increasing the readout speed and tracking the maximum intensity of the light spot to allow automatic tracking of light spots moving at high speeds. It is also equipped with power-down mode that effectively reduces power consumption during standby. The line-up of new profile sensors includes types with 512 (H) × 512 (V) pixels that offer a wider field-of-view (FOV) than currently available profile sensors having only 256 (H) × 256 (V) pixels.

This new profile sensor with an embedded computing circuit will help reduce the size, weight and cost of surveying equipment and will also offer effective ways to extend its applications to factory automation such as for welding robots.

We will be working to expand sales of this new profile sensor and open up a vast new range of applications.

Main Product Features

1. Embedded computing function

Until now, when using an image sensor or profile sensor for position sensing, an external controller was needed for processing the image data or projection data to detect the incident light position. This new profile sensor has a processing chip that contains a computing circuit for calculating the center-of-gravity and outputs the incident light position as coordinate data. This eliminates the need for an external controller.

2. High-speed output

The output functions include a partial read-out mode that utilizes only the signals from pixels in one part of the photosensitive area and a binning operation mode that handles multiple adjacent pixels as one pixel. These modes increase the read-out speed to a maximum frame rate of 83,333 frames per second.

3. Low power consumption

Power-down mode is included to minimize power consumption during standby. This will prove beneficial in applications relying on compact battery-driven devices.

Hamamatsu Photonics Deutschland GmbH

Arzberger Str. 10

82211 Herrsching am Ammersee

Telefon: +49 (8152) 375-0

Telefax: +49 (8152) 375-199

http://www.hamamatsu.com

Public Relations

Telefon: +49 (8152) 375-185

Fax: +49 (8152) 375-199

E-Mail: rfritsch@hamamatsu.de

![]()