Microtech Gefell – New measurement tools & turnkey test benches for simulated indoor and exterior pass-by systems

By Udo Wagner/Microtech Gefell/MTG

E-mobility changes the world of acoustical engineering. The development of a new vehicle generation is going along with immense progresses in technologies of test bench systems and in the world of acoustic measurement.

The e-mobility-world presents a host of new challenges for acousticians. In the century of e-vehicles noise emission is as low as never was possible in the time of combustion engines.

But to low noise emission is dangerous, especially for pedestrians. Legislators in mostly countries demand a minimum noise in the speed-range up to 20km/h and in reverse mode (European directive no.540/2014). These systems are called AVAS (Acoustic Vehicle Alerting Systems) and are obligatory since 1st of July 2019 in electrical, hybrid-electrical and fuel cell cars.

Creativity of sound-engineers is not limited. Prof. Stefan Sentpali says “People have a given expectation, how sounds an object. … The sound has to be high-grade, must not creak or grind … people know how vehicle are sounding in science fiction movies. They will orientate themselves also in case of electrical vehicles. They are sounding up to two octaves higher, high frequency like a quiet pleasant whistle…” [(DPA), „Zwischen ´Star Trek´und Stille: Sounddesign bei E-Autos“/OTZ 15.12.2020].

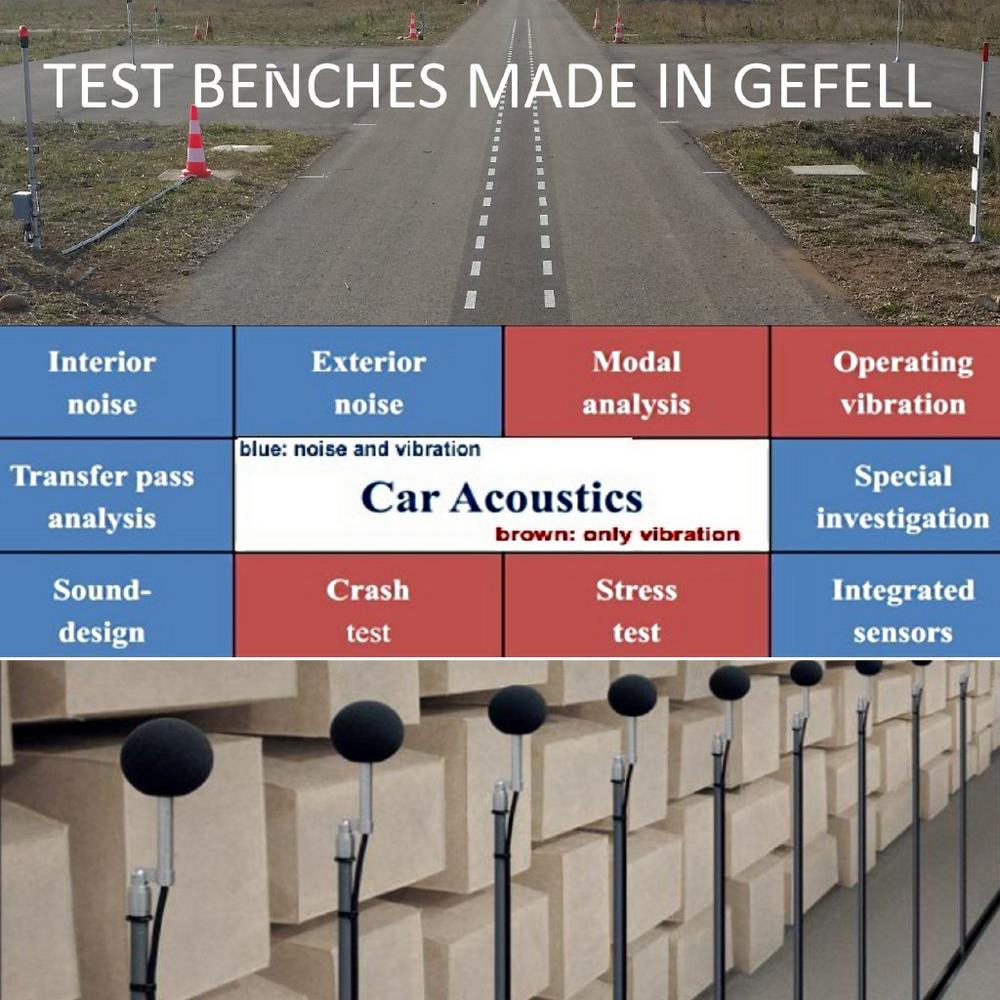

MTG provides a wide range of measurement tools and equipment for sound-engineers, designing the noise of e-vehicles, including both single measurement tools and turnkey indoor test benches for simulated pass-by and outdoor pass-by test bench systems.

In- and outdoor Pass-By measurement and e-mobility

Pass-By measurement conform to DIN ISO 362-1:2017-10 is a standard method for all approved vehicles, but the same installed test benches are suitable for the design of e-vehicle sound.

There are real pass-by test benches in weatherproof outdoor installations with two obligatory measurement microphones on one hand and on the other hand there are indoor simulation pass-by test stands with up to 64 microphone channels in very large indoor facilities with acoustic elements. It`s hard to imagine, but there are room-acoustic installations, which allow a measuring limit, covering a range from 40Hz to 20kHz and more. That requirement for the low frequency limit came from combustion engines, but it’s usable for sound design in the e-mobility world too.

Our human ears are sensitive in a frequency range between 16Hz and 20kHz, while the loudness sensation extends from 0dB, which is a sound pressure from 20µPa, to 130dB. The lowest limit is called hearing threshold, the upper limit is called pain threshold. Frequency- and loudness sensation in nature is everything else than linear. That fact is important, when we want to create a sound, which is “Music to my ears” [Automotive testing technology international, Nov. 2020, p. 62ff].

In opposite to our human ear, a measurement microphone is a sensor with a very linear frequency response. Only with filtering, e.g. conventional A-weighting or psychoacoustic evaluation in software systems, analysed signals come very close to our human sensation.

Already in case of the right microphone choose the changing measurement world becomes noticeable. While traditional combustions engines exhibit their spectral noise dues in the frequency range lower than 3kHz, electrical drive systems are audible in the 6kHz-, 8kHz- or 10kHz range. Up to 3kHz a mostly all high standard microphones, which are sound pressure receivers by their physical characteristics, have a very linear amplitude response. Upper 3kHz it’s very important to choose the right type of frequency-response-type for a microphone – free-field or random field type. Also the influence of the foam-windshields, which should lower the acoustical disturbances of wind turbulences around the microphone body, is important, because depending of the foam density, high frequency spectral dues are attenuated more or less. With windshields, which are not conform to microphone manufacturer specification, the microphones fall out of the sound-level-meter or microphone tolerance-field at the lower limit.

The measurement microphone as a sound pressure receiver without a directional sensitivity for sound waves should have an exact omnidirectional characteristics. This is not completely right in the acoustical frequency range upper than about 5 kHz, because the wavelength comes the same dimension as the microphone itself. That fact causes a difference in sound-level measurement results for example in a pass-by measurement, if microphones of a special type, like free-field with an exact linear amplitude response on axis, are installed vertical or horizontal in respect of their own axis. In other words, the important question is, if the membrane looks to the heaven or to the moving vehicle. That fact is not described exactly in the pass by standard ISO 362… up to its current version from 2017.

Measurement equipment manufacturers like Microtech Gefell utilise the same effect, by installing microphones for pass-by measurement in a vertical position with simultaneous use of random (diffuse) field microphones.

This type should usually ensure, that a microphone gets a linear frequency response in an echoing environment, because there are less reflection and pressure build up effects in that kind of sound-field. Besides such a microphone type exhibits an exact linear class 1 response in 90 degree off-axis during application in free-field conditions. So it is an ideal instrument to do pass-by measurements, because one hand a vertical microphone optimally protected against rain, humidity and wind and on the other hand, the acoustical pattern is exact circular around its axis, which does mean, the position of the car while driving by is not causing a wrong measured noise level value because of the polar pattern effect and the angular position.

The newest product, which is developed by Microtech Gefell GmbH, is called WME 980 CN (community noise) includes exactly these acoustical and practical contexts and is a perfect tool for standard conform measurements as well as modern sound design. With its frequency response and polar pattern it is allowed to be used with a sound-level-meter class 1 conform to DIN IEC 61672.

Sound investigation of acoustical components by using of hemispherical microphone arrangements and sound-intensity probes

Of growing importance is the newest application for sound investigation of acoustical components by using of hemispherical microphone arrangements.

In the field of e-mobility, e.g., the measurement of tyre noise is an essential task. While engine and gearbox noise have been important parts in the “combustion era”, the e-vehicle tire noise become more and more important. That part of noise emission was covered by the higher noise of the traditional elements. There are existing special tire noise test benches, where moving tires are installed on a separately driving roller dynamometer, surrounded from a microphone-hemisphere.

SIS 190 – Sound-intensity probes – in addition to a hemispherical microphone arrangement

Sound-intensity probes are two-microphone arrangements with exact selected phase responses. These instruments are used for sound-power measurements and are conform to standard DIN EN IEC 61043. As it were sound-intensity probes can be used for location of partial components of sound emission. It has not to be explained more, that such a product from Microtech Gefell like SIS 190 double, which covers the complete sound frequency range from 40Hz to 12kHz, is another one professional tool for the sound designer.

Summary

At the end we come back to the fact, that the future sound development in the time of e-mobility comes closer to the composition of music. The high professional Microtech Gefell microphones are bringing together the experiences technical acoustics and recording business, what is visible = audible in the wide range of its studio microphones: “We in Gefell are measuring, what you are hearing AND are hearing, what you are measuring”.

Acoustic measurement technology since 1928

The Microtech Gefell GmbH is manufacturer of high quality, handmade measurement and studio microphones founded 1928 by Georg Neumann.

Besides the company offers calibration and services for all manufactured products.

The Measurement technology includes 1", ½" and ¼" measurement capsules, measurement preamplifiers for different connection techniques (Conventional Lemo, ICP®, Phantom P 48 XLR, Digital USB AES 42 XLR), outdoor and environmental microphones, microphone arrays, sound intensity probes, power supplies, calibration devices as well as turnkey solutions (e.g. special test benches for car acoustics).

Microtech Gefell GmbH

Georg-Neumann-Platz

07926 Gefell

Telefon: +49 (36649) 8820

Telefax: +49 (36649) 88211

https://www.microtechgefell.de

Sales Director

Telefon: +49 (0) 36649 882-20

Fax: +49 (0) 36649 882-11

E-Mail: u.wagner@microtechgefell.de

![]()