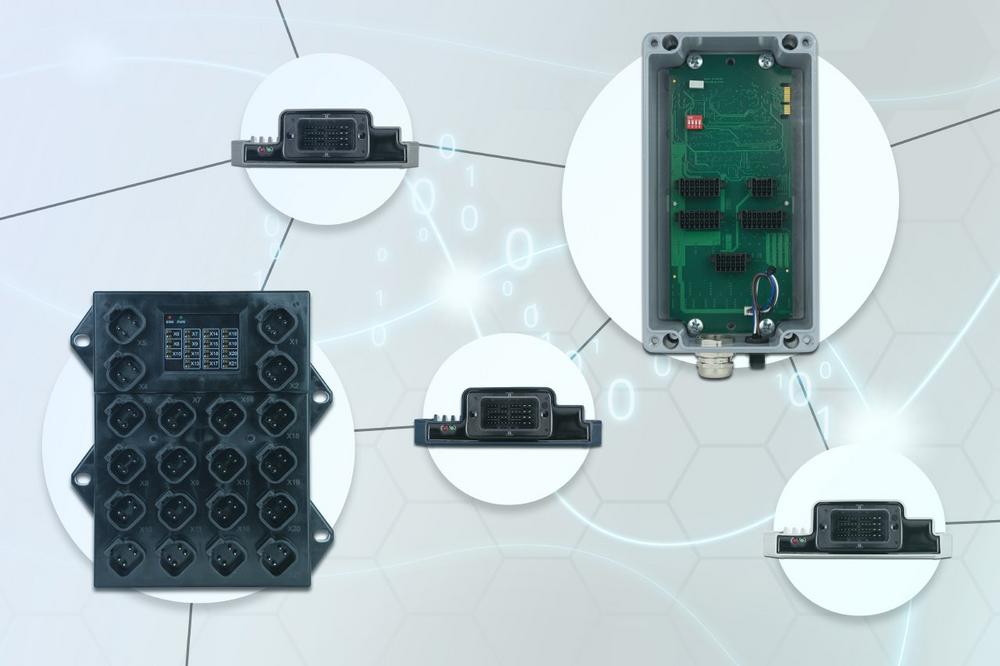

On-target solution – whichever the use case: Each model type is geared to specific functional requirements, making the Jetter range of I/O mod-ules an ideal complement or expansion to any control system in mobile machinery, commercial and special-purpose vehicles. Communication via CANopen® allows them to integrate into conventional CAN networks. Pro-tected by a rugged, potted housing, expansion modules are ideally suited to be used in the demanding operating environments typical of mobile au-tomation systems. The Jetter I/O model range offers a variety of cabling, input and output options.

There is a solution for every cabling requirement

Depending on the use case, each expansion module must meet different cabling requirements. The JXM-IO-E30 model type reduces cabling efforts to an absolute minimum: It comes with a reference output supporting standard sensors and pre-processing applications. This I/O node is gener-ally used by spreader vehicles. Where machinery is changing regularly, the benefits of the JXM-IO-EX30 expansion module come into play: While the hardware is identical to the JXM-IO-E30 model type, the 48-pin molex plug was replaced by 4-pin DT plugs. This innovative cabling approach uses standard cables thus facilitating swift plug & play connectivity in the field. It is applied, for example, to realize automation tasks for slurry tank-ers and manure spreaders.

The heavy-duty JXM-IO-EW30 modes is designed to cope with the rough operating conditions in special machinery. This model type does not re-quire any plug-in connectors. The rugged enclosure combines with field-proven cable glands and WAGO MCS mini HD connectors to harness maximum wiring flexibility and reliability.

Made for linear drives

The 30 series model trio differs from the JXM-IO-E31 mainly in the type of output. While the JXM-IO-E30, JXM-IO-EX30 and JXM-IO-EW30 models feature high-current paths, as is required for hydraulic valves, the JXM-IO-E31 has eight half bridges, which are particularly well-suited for linear drives as installed in municipal vehicles. A typical use case would be the controlling of brushed DC motors in self-propelled mobile machinery.

Strong input performance

Unlike the JXM-IO-E31 model type, the JXM-IO-E32 expansion module’s I/O configuration is input-focused enabling it to manage a wide range of distributed tasks. Its 16 inputs include analog and high-resolution sensor inputs – of which eight are thermal sensor inputs supporting PT1000 sen-sors, thereby further enhancing the module’s scope of application. This node is mainly used to integrate thermal sensors and high-resolution pres-sure sensors in mobile machines.

Scalability under focus

Whether municipal vehicles or agricultural machinery – mobile automation solutions engineered by Jetter offer advanced scalability. Carefully blend-ing software, hardware, and operating concepts, Jetter system solutions are synonymous with full-service solutions.

Jetter AG is a leading provider of automation systems for the machinery and plant engineering busi-ness, as well as for the process technology industry. These systems have been applied both in in-dustrial and mobile automation for decades. Jetter solutions are noted for their outstanding system integrity and diversity thus simplifying handling for the customer.

R&D and production of the automation specialist are located both at the headquarters in Ludwigs-burg and in Tettnang near Lake Constance. Around 300 employees at the German production sites, at the subsidiary in Hungary and China, at the sales and application branch in Italy, as well as the global support network help Jetter to realize worldwide individual customer requirements as quickly as possible.

Jetter focuses on the packaging and filling, handling and assembly, window manufacturing, municipal vehicles, agricultural machinery and glass container production industries.

Bucher Automation AG

Gräterstraße 2

71642 Ludwigsburg

Telefon: +49 (7141) 2550-0

Telefax: +49 (7141) 2550-425

http://www.jetter.de

Leiter Marketing

Telefon: +49 (7141) 2550-462

Fax: +49 (7141) 2550-425

E-Mail: JWeyershaeuser@jetter.de

Marketing

Telefon: +49 (7141) 2550-562

Fax: +49 (7141) 2550-425

E-Mail: sglemser@jetter.de

![]()