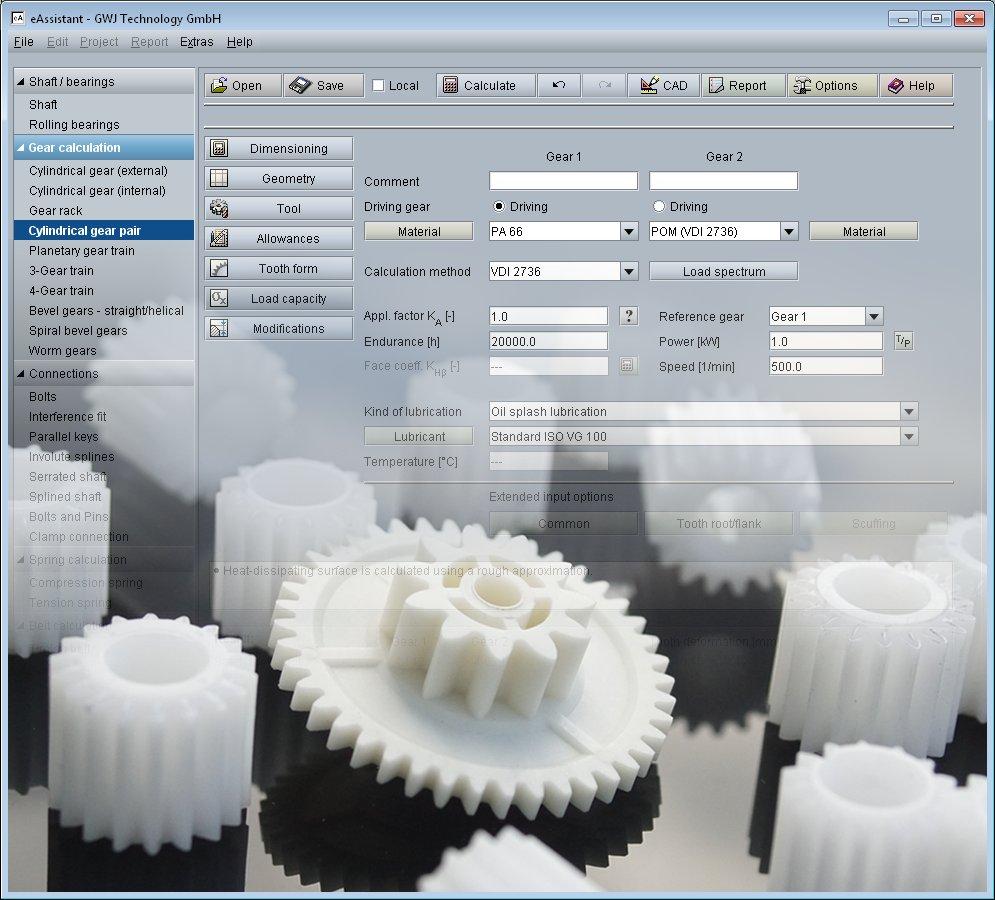

In addition to the common calculation methods for the load capacity DIN 3990, ISO 6336 and ANSI/AGMA 2101, the calculation method VDI 2736 for plastic gears was added to the cylindrical gear module. The first plastic materials were added to the general material database. For this, the temperature-dependent material properties such as fatigue strength and E-module were approximated in detail from available diagrams in VDI 2736 and stored accordingly. These are used to determine the material properties for the calculation of the load capacity using the tooth root and flank temperatures automatically calculated according to VDI 2736.

If the calculated tooth flank and tooth root temperatures exceed the maximum operating temperatures of the plastics, a corresponding warning is given.

In order to calculate the tooth flank and tooth root temperature, the user can modify the housing design, the heat-dissipating surface as well as the heat transfer and heat resistance as an alternative to the automatic default settings.

Pairings of plastic/plastic as well as plastic/metal are supported. Furthermore, metal/metal pairings are also available in order to compare calculation methods for metallic gears.

The calculation of load spectra is also possible for the load capacity calculation according to VDI 2736. In addition, "Dry run" was added to the lubrication types for VDI 2736.

Visit www.gwj.de for more information or contact GWJ at +49 (0) 5311293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology stands for high-quality products and professional software development for mechanical engineering to support engineers and designers in their daily work.

The GWJ product range of innovative calculation software is wide – from standard software for classical machine elements with 3D CAD integration modules to the determination of whole systems up to a complex special software for 5-axis milling of gears.

There are common features that all GWJ solutions share – intuitive design, sleek interface, easy to use and suitable applications for all users from beginner to very advanced. GWJ is constantly working on software enhancements and adding new features to the system in order to keep the applications up-to-date. Professional competence, state-of-the-art technology, a demand for high quality and excellent customer services are the key factors in GWJ´s business philosophy to give the customers the best possible service and advice to obtain new competitive advantages.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

Geschäftsführer

Telefon: +49 (531) 1293990

Fax: +49 (531) 12939929

E-Mail: g.weser@gwj.de

![]()