Find similar components by geometry and size

Using the Geometric Similarity Search GEOsearch, engineers can quickly and easily search for geometrically similar components within their parts libraries, starting from a roughly designed part or a 3D sketch.

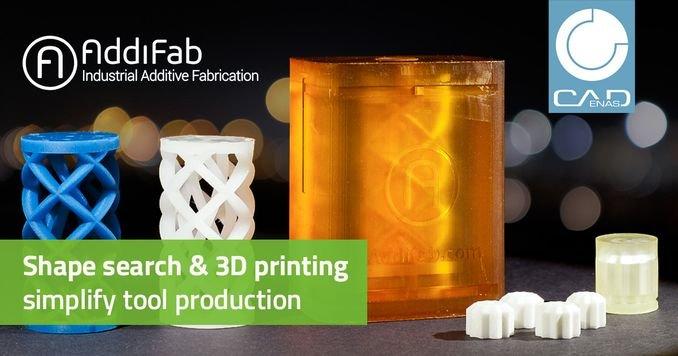

In addition to the shape they are looking for, users can also use CADENAS‘ GEOsearch to define the desired size of the printed tool in advance of the search. Because when printing with the AddiFab technology, the maximum size of 10 x 10 x 20 cm is of decisive importance. In this way, workpieces that are too large can be effectively excluded.

Due to the significantly reduced costs of 3D printing tools in prototype development and small series production, PARTsolutions in combination with the AddiFab printing technology offers an enormous savings potential.

3D printing of prototypes and small series tools within one day

With the AddiFab technology, tools can be 3D-printed in one day. These tools are of a quality suitable for the creation of prototypes in product development and small series production and are many times cheaper to produce. The technology also enables the production of complex tools by means of 3D printing, which cannot be molded with conventional injection mold tooling. "3D printing leads to great savings through shorter delivery times and very low entry costs. With PARTsolutions, we may provide users of Freeform Injection Molding with an ideal solution for prototype production and small series production for injection molding," says Lasse G. Staal, CEO at AddiFab.

Further information about AddiFab at: www.addifab.com

More information about the Geometric Similarity Search of the Strategic Parts Management PARTsolutions of CADENAS at: www.cadenas.de/en/products/partsolutions/finding-information/motivation

As well as in the CADENAS brochure "Finding instead of searching“

CADENAS GmbH

Schernecker Str. 5

86167 Augsburg

Telefon: +49 (821) 258580-0

Telefax: +49 (821) 258580-999

http://www.cadenas.de

Telefon: +49 821 258580-500

E-Mail: presse@cadenas.de

![]()