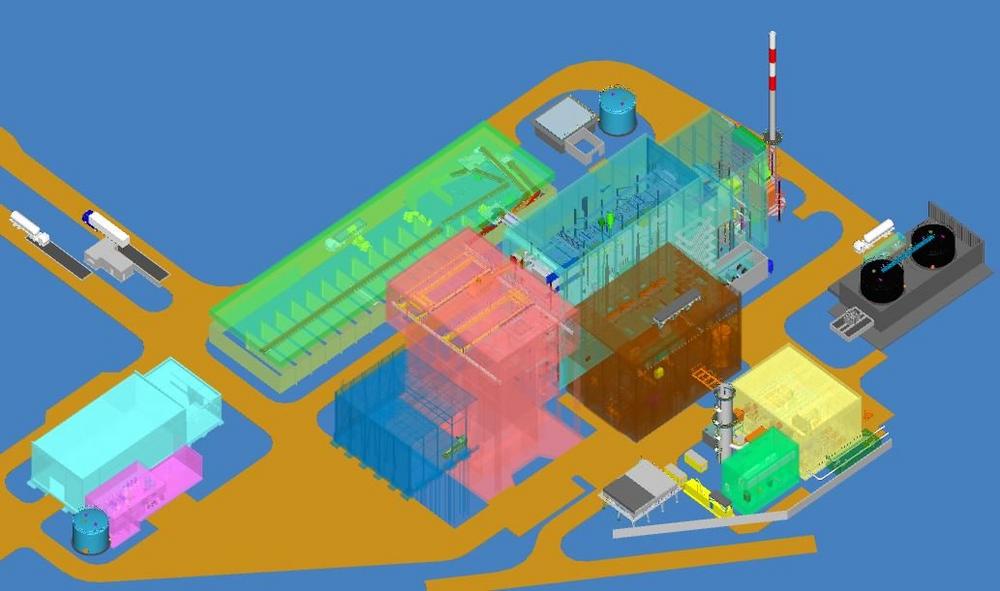

Contracted by the plant owner and operator, Dobra Energia dla Olsztyna, the consortium will deliver the entire one-line plant including combustion grate, boiler and dry Circoclean flue gas cleaning, and Selective Catalytic Reduction (SCR). Furthermore, civil works and two gas-fired peak load boilers (PLB) along with site management will be part of the supply.

Commenting on the project, Gerhard Lohe, Product Director Waste-to-Energy at Doosan Lentjes, says: “This project is the first waste-to-energy plant that DHIC and Doosan Lentjes are executing together. It proves that international EPC experience in large-scale plant construction projects as well as a rich heritage and competence in modern WtE technology is a strong combination of capabilities that meets the demands of the industry. Customers can therefore expect an interface-optimized delivery of the project from one source. Our two companies can look back on many years of experience in the execution of large, but also smaller power plant projects all over the world. The joint entry into the global WtE market now represents the next step in the exploitation of synergy effects within the Group.”

Co-funded by the EU, the plant will meet all European requirements with regard to recycling and disposal, while, at the same time, complying with the emission limits according to the new BREF documents (Best Available Techniques Reference).

The new plant, scheduled to be completed in 2023, will be capable of processing up to 110,000 tons of refused derived fuel (RDF) per year produced by the citizens of the greater Olsztyn area. Covering roughly 30% of the district heating demand in the region, the new plant will help to compensate for the heat loss that will accompany the closure of the local coal-fired Michelin power plant in the near future. This will ensure a continuously reliable and secure supply of district heating to the local citizens. At the same time, using the energy contained in the waste offers a sustainable alternative to fossil fuels. In addition, the thermal treatment of the waste makes it possible to reduce the landfill space required.

Commenting on the project, Mariusz Marciniak, Director for Central and Eastern Europe, says: “The new plant in Olsztyn will be a milestone in improving the waste management infrastructure in Poland. It is the eighth plant of this type to be built in the country and it is crucial for achieving the objectives of the EU waste hierarchy. This hierarchy gives priority to energy recovery from waste over simple landfill and, thus, requires the energy potential of solid waste to be harnessed. One of the eight plants, the one in Krakow, was built with the involvement of Doosan Lentjes as technology provider for both grate and boiler. The plant benefits from the technological experience of Doosan Lentjes and has been reliably converting municipal waste from the Krakow region into energy since 2013. Doosan Lentjes will apply the experience gained in Krakow to the second project recently won on the Polish market to the benefit of the customer and final client, the local energy provider, MPEC Olsztyn.”

Doosan Heavy Industries & Construction is a leading EPC contractor offering a wide range of services ranging from the manufacturing of castings and forgings, power generation systems to the construction of power plants.

Doosan Lentjes is a specialist in the delivery of proven and reliable waste-to-energy technology, converting millions of tonnes of waste into valuable energy every year. This helps customers all over the world reduce their waste volumes and simultaneously provide a sustainable energy source.

Doosan Lentjes is a global supplier of processes and technologies for steam and power generation from both sustainable and conventional fuels. Our specific areas of expertise include key technologies for energy recovery from waste, sewage sludge incineration, circulating fluidised bed boilers and flue gas cleaning systems. For more than 90 years, we have been pioneering innovative energy solutions and convert millions of tons of waste into valuable energy every year.

Doosan Lentjes is part of a powerful combination of companies united under the Doosan Group to deliver complementary technologies, skills and value to customers the world over.

Doosan Lentjes GmbH

Daniel-Goldbach-Straße 19

40880 Ratingen

Telefon: +49 (2102) 166-0

Telefax: +49 (2102) 166-2500

http://www.doosanlentjes.com/en/

Marketing Manager

Telefon: 021021661476

Fax: 021021662476

E-Mail: diana.baganz@doosan.com

![]()