"We were able to respond in a short time to numerous inquiries seeking a solution for filling dry ice into shipping boxes or transferring large dry ice containers into shipping boxes," says Marco Pellegrino, Managing Director of ASCO CARBON DIOXIDE LTD. The company is expanding its dry ice technology portfolio with two dosing units that are used particularly in the pharmaceutical, logistics and food industries.

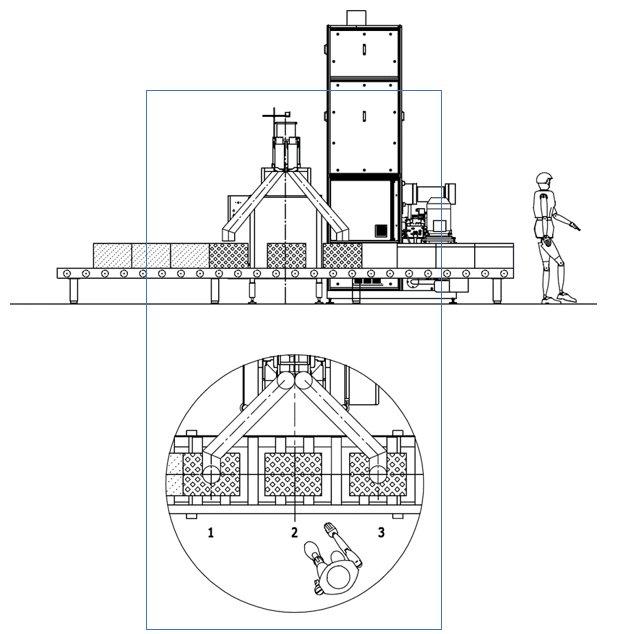

The new dry ice filling system (dosing system) is compatible with all ASCO pelletizers and, in its standard version, consists of two dry ice production lines with dry ice dosing units and a conveyor system depending on capacity requirements. This enables automated pre-filling of (shipping) boxes with freshly produced dry ice. Subsequently, vaccine doses, for example, are placed in the box and after that automatically filled with dry ice again. Finally, the box only needs to be sealed for shipping.

The ASCO dry ice refilling system is particularly suitable for the pharmaceutical, logistics and food industries when the dry ice is already purchased ready-made. With the new solution, the dry ice delivered in containers from the supplier, can be transferred to the dosing unit by a lifting process. From there, weight-based dosing of the dry ice through predefined recipes enables automatic filling into customer boxes. This makes it possible to use the dry ice as quickly as possible with a minimum of man power.

Since maintaining the cold chain is of crucial importance, especially in the food and pharmaceutical sectors, ASCO CARBON DIOXIDE LTD has been concentrating intensively on the provision of the two dry ice filling systems in recent weeks. The challenges of shipping COVID-19 vaccines, producing a large quantity of dry ice in a short time and dosing it into shipping boxes, reinforced the company’s efforts in this regard.

The Swiss ASCO CARBON DIOXIDE LTD is a globally operating company that offers complete solutions for CO2 and dry ice. The range of services includes CO2 production and CO2 recovery systems, ASCOJET dry ice blasting machines, dry ice production machines, CO2 cylinder filling systems, CO2 vaporisers, CO2 storage tanks, CO2 dosing systems for water neutralization and various other CO2 and dry ice equipment.

Thanks to this broad product range and more than 130 years of practical experience in the comprehensive CO2 and dry ice sector, the customer benefits from individual, complete CO2 solutions from a single source. ASCO has been part of the international industrial gases company Messer Group since 2007 and is its centre of competence for CO2.

ASCO KOHLENSÄURE AG

Industriestraße 1

CH8590 Romanshorn

Telefon: +41 (71) 4668080

Telefax: +41 (71) 4668066

http://www.ascoco2.com

Marketing & Kommunikation

Telefon: +41 71 466 80 68

E-Mail: fabian.weber@ascoco2.com

![]()