New and promising manufacturing methods such as 3D printing of PEEK implants must be able to compare with the golden standard technologies of molding and milling. Only if results can be achieved that stand up to direct comparison in a reproducible manner an emerging technology such as 3D printing of PEEK filaments can be used as a validated, advantageous alternative in medical technology.

TRH – next level technology for 3D printed PEEK in medtech applications

The key advantage of Orion Medical’s additive manufacturing technology is its Thermal Radiation Heating (TRH) system, which enables 3D printing of medical devices with injection molded strength and nearly 100% density.

Only if the manufacturing method is validated, 3D printing of polymer implants make sense, both in patient-specific applications and in industrially scalable quantities.

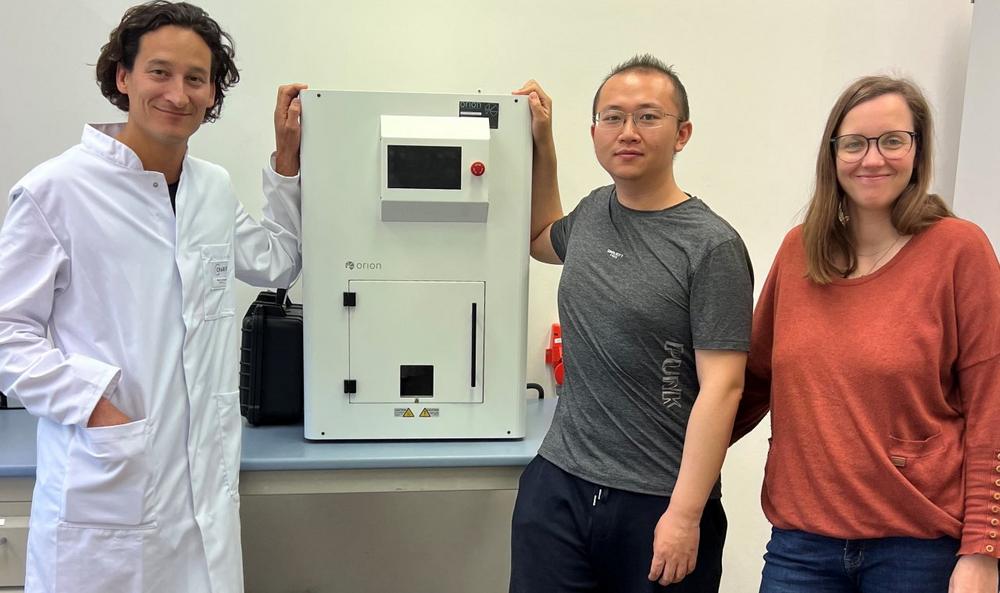

In a direct comparison of different manufacturing processes, the engineers of Orion Medical GmbH, together with the materials specialists and clinicians of Charité Universitätsmedizin Berlin under the direction of Prof. Dr. Andreas Schwitalla, faced the challenges that biomechanics dictates to manufacturers of dental implants.

"When comparing different printing systems, the M-150 Series from Orion Medical emerged as our favorite 3D printing system for medical devices, especially in terms of density and mechanical strength in all three directions. With the latest adjustments and the improvement of their TRH technology, Orion managed to qualify its printer for medical technology applications”, explains Prof. Schwitalla. “Now we will benefit from these modifications in our further design and development efforts of polymeric or hybrid dental implant applications.”

M-150 Printer to be qualified for orthopedic applications

Another M-150 printer will be delivered in the next weeks to FH Kärnten, Austria: Together with an ISO and MDR certified implant manufacturer Prof. Spintzyk will qualify the medical printer for its use with orthopedic implants.

With thermal radiation, the heat penetrates the material so that the layers really fuse together. “The result of TRH are parts or components with unique uniform strength, higher density, and stability. Orion’s technology solves the anisotropic nature of FFF 3D printing, even for difficult-to-print implantable-grade materials like PEEK, PPSU and other high performance polymers. This results in fully isotropic properties qualified for long-term implantation", explains Christoph Koslowski, Managing Partner, Orion Medical GmbH.

QM System according MDR (EU) 2017/745, following ISO 13485:2016

To act as a qualified supplier for its customers according to ISO 13485:2016 and MDR, Orion Medical follows the requirements for a QM system as demanded by MDR 2017/745 in Art. 10. In addition, Orion Medical has started its ISO 13485:2016 certification process that is expected to be completed in Q3 2022.

About Orion Medical GmbH

Orion Medical is a privately held company focused on developing and producing additive manufacturing technologies to solve today’s complex problems and create innovative solutions for tomorrow’s medical device industry. Originally focused on developing highly regulated aerospace solutions, Orion AM developed the A150 Series printers using its proprietary Thermal Radiation Heating (TRH) technology. With its knowledge of highly regulated environments and very complex parts using high performance polymers, Orion AM applied its knowledge to the development of the first medical printer for Orion Medical, the M-Series. The medical 3D printer is designed and structured to easily adapt to any clinical scenario. It can create 3D prints based on patient-specific anatomy. This allows surgeons to plan, visualize, simulate, and develop a better understanding of potential solutions for congenital or acquired pathologies.

Orion Medical offers its customers and all parties interested in 3D printing of medical devices additional services besides the Medical Printers of the M-Series. These include design support, design transfer of implant concepts for 3D printing, but also regulatory assistance such as compiling of product files, advice in terms of ISO 13485:2016 and the MDR (EU) 2017/745, specifically advice regarding Article 5a of the MDR (EU) 2017/745: Placing on the market and putting into use – manufacture AND use in healthcare facilities.

Orion Medical GmbH

Handelsregister: Kt. Zug, Schweiz

Klostermatt 6, 6330 Cham, Switzerland

Email: christoph@orion-am.com

Web: www.orion-am.com

MedDEV News, MedDEV Quarterly News, MedDEV Featured Publication Single Release:

The best way for young researchers, start-ups and SMEs to publish results they think are worth sharing.

Fast. Transparent. Peer-reviewed. Open-Source. ISSN-indexed. DOI-identifiable.

In cooperation with:

Stiftung für Medizin-Innovationen

Medical Innovations Incubator GmbH

MedDEV News

email: redaktion@meddev.news

www.meddev.news

MedDEV News

Sonnenstraße 35

CH8280 Kreuzlingen

Telefon: +49 (160) 7809628

https://meddev.news/

orion medical gmbh

E-Mail: medical@orion-am.com

![]()