Networking and connectivity are hot topics in industrial production, and it therefore makes sense that advances in this field are also implemented as comprehensively and efficiently as possible in robotics. At Hannover Messe 2023, Stäubli will be showing how this works in practice and what advantages the networked monitoring of robots offers with the launch of its SCOPE platform.

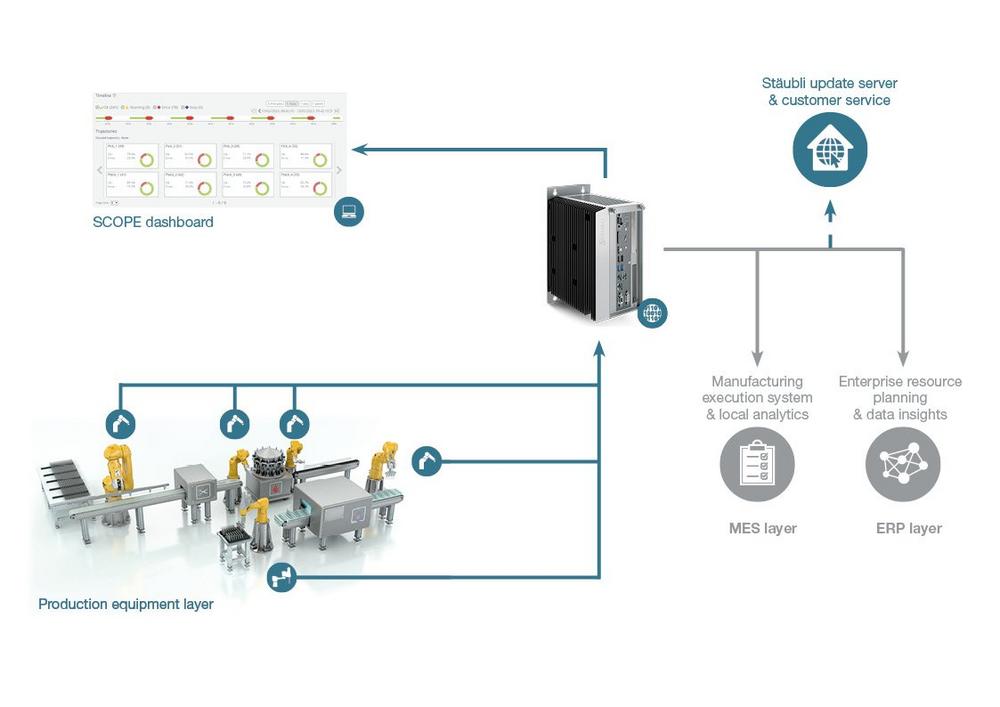

The acronym stands for “Smart, Connect, Optimize, Prevent and Enable”, which neatly summarizes the nature of this digital solution for robot fleet monitoring. The on-site platform aggregates, processes, analyzes and visualizes the robot-specific data. Users can view a multiplicity of relevant operating data for each individual robot system on a central dashboard. This creates the conditions for detecting irregularities or gradual departures from spec, and for taking appropriate preventive action before quality is compromised, components start to get damaged or the production line even grinds to a standstill.

The real-time data collected by SCOPE can also be communicated to higher architectures layers or databases and analysis tools. SCOPE is able to forward data via mqtt, http response and websocket. Connection to the ERP, SCM or MES system of the user is therefore also possible.

Transparency across the entire fleet

The benefits conferred by SCOPE are immediately apparent. Manufacturing professionals always have an overview of the status of all robots. In the near future they can evaluate this data manually and respond instantly if necessary, or they can use machine evaluations for predictive maintenance, with the option of running their own AI-controlled optimization processes.

Furthermore, SCOPE allows future functionalities and updates to be loaded and used in practice quickly and with minimal effort. In all cases, SCOPE provides users of Stäubli robots with the right tool to minimize downtime, to optimize the productivity of their automated systems and to extend the life cycles of their production equipment.

Stäubli Robotics is a leading global player in robotics, consistently delivering engineering as effective and reliable as our service and support. A complete solutions provider for digitally networked production, Stäubli offers a broad range of 4- and 6-axis robots including robotic arms designed specifically for sensitive environments, autonomous mobile robots, driver-less transport systems (AGVs) and cobots for human-robot collaboration.

Stäubli Tec-Systems GmbH Robotics

Theodor-Schmidt-Str. 19/25

95448 Bayreuth

Telefon: +49 (921) 883-0

Telefax: +49 (921) 883-3244

https://www.staubli.com/de/de/robotics.html

Manager of Marketing and Division Business-Marcom

Telefon: +49 (921) 883-3212

E-Mail: s.koban@staubli.com

![]()