As a leading global company listed on the Chinese stock exchange, Guandong Anda Automation Solution Co., Ltd. manufactures and sells technological solutions for controlling the application of fluids in manufacturing processes to customers from a wide range of industries. The efficient and high-quality system solutions developed by ANDAAS are used in high technology markets, such as smartphone manufacturing, aerospace, e-mobility and medical care.

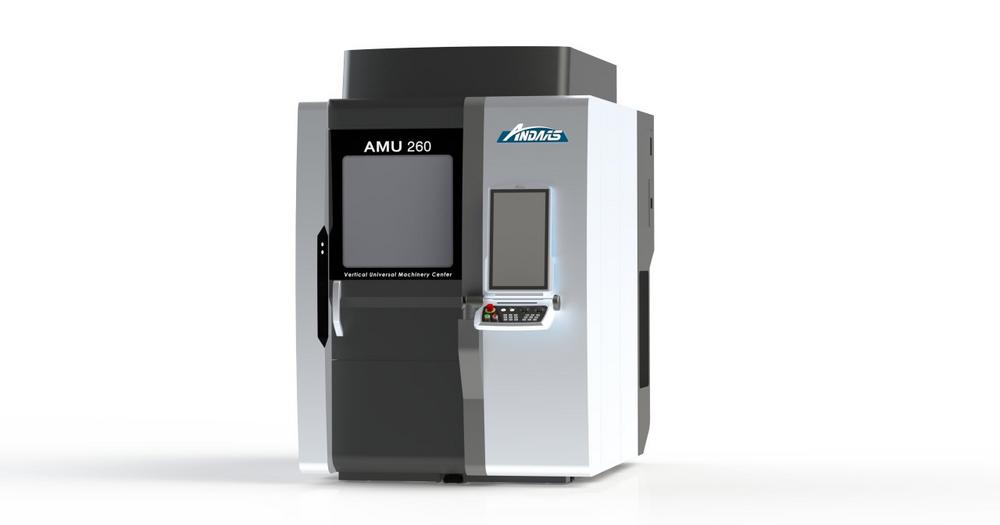

Since July 2022, ANDAAS has been systematically expanding its portfolio by developing 5-axis milling machines. For the latest project, the state-of-the-art AMU260 machine tool, ANDAAS relied on the expertise of NUM as a CNC technology leader.

NUM’s high-performance hardware together with NUMhsc targeted software algorithms, delivers a proven total solution for achieving maximum quality at the highest speeds in 5-axes machining.

The AMU260 also features NUM’s advanced Flexium 3D simulation software. About the control system, NUM supported the project in the creation of the ICS system, which provides the user with a camera, the VTM tool measuring system and a WeChat function. The tool measuring system (VTM) was fully integrated into the CNC system by NUM and ensures maximum precision in the machining processes. NUM also assisted in the development of a digital machine tool control panel.

The AMU 260 machine key features are:

- Central cooling system for enhanced performance

- Automatic lubrication system for smooth operation

- Automatic tool change system with 40 tools (optional 140 tools)

- High-speed spindle motor with up to 24,000 rpm

- Advanced control system with NUM Flexium+ 68 controller and 23.8" Touch control panel

- Real-Time Tool Center Point (RTCP) function for precise machining

- Customized ICS software help the intelligent machining and connectivity

- Chip container and cooling systems for efficient chip management

- One-year mechanical warranty and two-year controller warranty for peace of mind

In addition to NUM, ANDAAS opted for the support of its strategic partner Shanghai Weiyan Precision Technology Co., Ltd (WPT) to support the development of the AMU260. For the AMU260 project, they supplied an image processing-based tool monitor (VTM) for two-dimensional CCD imaging of the cutting tool for precise contour monitoring in the AMU260 project.

"In collaboration with ANDAAS, our esteemed partner, we’ve once again demonstrated our prowess in developing cutting-edge technology in 5 axes milling application. The AMU260 milling machine which integrated of most Flexible and opened NUN CNC controls, a testament to innovation, combines high-performance hardware and full customized functional software to deliver unparalleled precision and efficiency in machining", adds NTC Manager China Mr. Longwei Jiang.

NUM AG

Battenhusstrasse 16

CH9053 Teufen

Telefon: +41 71 335 04 11

Telefax: +41 71 333 35 87

https://www.num.com/

Telefon: +86 (21) 6882-0958

Fax: +86 (21) 6882-0959

E-Mail: sales.cn@num.com

Telefon: +86 (20) 2232-5686

E-Mail: sales.cn@num.com

CMO NUM Group

Telefon: +41713350411

E-Mail: jacqueline.boeni@num.com

![]()