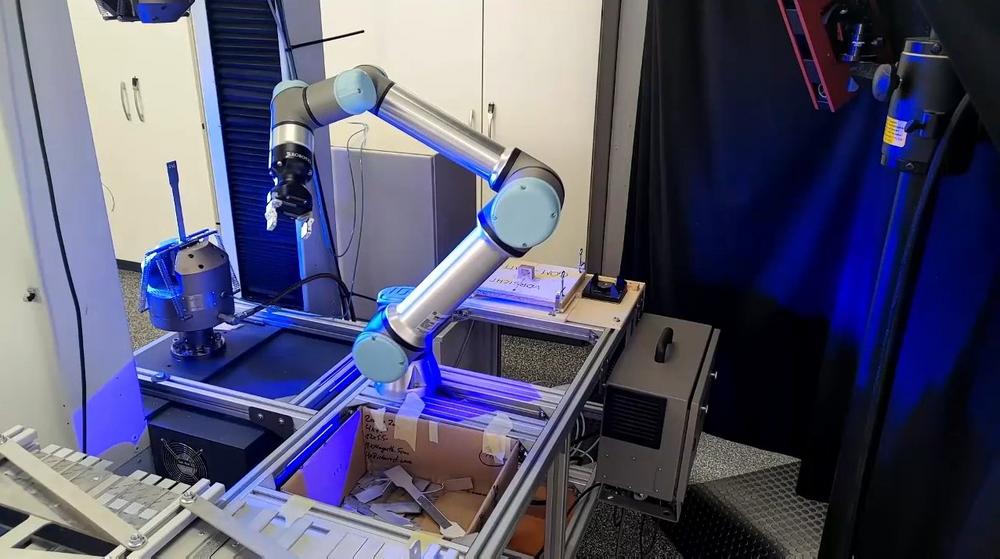

"Tests on classic and modified tensile specimens are key for the timely and accurate identification of material properties, as well as the subsequent calibration of material models all the way up into the damage and failure regime – both of which are required by our customers for their simulations in crashworthiness simulations. We are pleased that, after only a few months of development, we have now been able to further improve our quality and speed requirements by automating the testing and the accompanying evaluation algorithms," says Professor André Haufe, head of the DYNAmore MCC.

About AIMM

The use of reliable and precise simulation methods is of fundamental importance for the development of future, efficiency-optimized and low-emission vehicle concepts. The aim of the Artificial Intelligence for Material Models (AIMM) research project is to supplement or replace the classic model-based constitutive laws with an alternative, data-driven material modeling approach. Especially regarding the use of new materials, whose mechanical behavior is becoming increasingly complex, the limits of conventional material laws are to be overcome. In AIMM, the focus will be on the faster use of new materials, the development of associated new test concepts for generating the necessary training data and the shortening of the characterization and modeling phase through automation of the processes by means of a simplified approach for predictive CAE applications.

Ressources:

YouTube video: https://youtu.be/wOpCdxRruIU

As a software and development service provider, DYNAmore offers a product portfolio that includes the finite element software LS-DYNA, the pre- and post-processor LS-PrePost, the optimization software LS-OPT as well as numerous FE models for crash simulation (dummy, barricade, pedestrian, and most recently the human model HANS). The simulation suite LS-DYNA is co-developed by DYNAmore GmbH. DYNAmore has many years of project and development experience in model development and simulation industry (process simulation, passenger protection, vehicle crash) in all areas of mobility (aerospace, rail and motor vehicles).

For questions regarding applications and test licenses DYNAmore is at your disposal.

DYNAmore is located in Stuttgart, Dresden, Ingolstadt, Berlin, Langlingen, Braunschweig, Munich, Zurich (CH), Linköping (S), Gothenburg (S), Turin (I), Versailles (F) and Dublin, Ohio (USA).

DYNAmore Gesellschaft für FEM Ingenieurdienstleistungen mbH

Industriestr. 2

70565 Stuttgart

Telefon: +49 (711) 459600-0

Telefax: +49 (711) 459600-29

http://www.dynamore.de

Agentur Inhaber

Telefon: +49 (0) 80 92 – 8 35 50

E-Mail: albert.oswald@werbos.de

Telefon: +49 (711) 459600-0

Fax: +49 (711) 459600-29

E-Mail: info@dynamore.de

![]()